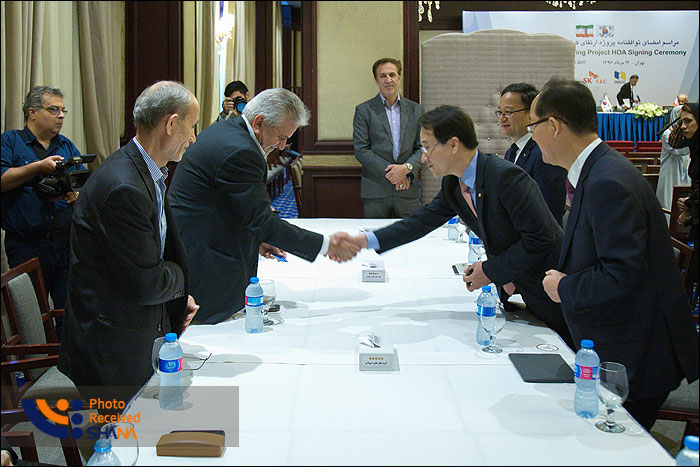

The agreement was signed between SK Engineering & Construction (SKEC) and Oil Design and Construction Company (ODCC) in Tehran. The signing ceremony was overseen by Abbas Kazemi, CEO of National Iranian Oil Refining and Distribution Company (NIORDC).

Gholam-Reza Baqeri Dizaj, CEO of Tabriz Oil Refining Company, says the refiner attracts foreign investors due to such advantages as ownership of a 50% stake in Tabriz Petrochemical Plant, proximity to five countries and supplying products of its own brand.

In an interview with Iran Petroleum, he said that the signature of deal with the South Korean firm would help the company enter regional and global market.

The following is the full text of the interview he gave to Iran Petroleum:

Q: When was Tabriz oil refining company established?

A: The basic design for the Tabriz oil refinery was done by the American UOP company in 1974 while Italy's Snamprogetti carried out the detailed design. The refinery became operational in February 1978 with a rated refining capacity of 80,000 b/d. In 1992, the oil refining capacity of this company rose to 110,000 b/d. The company was privatized in 2010. It has currently 15 refining units to process crude oil and produce petroleum products, and 8 utility units to support production.

Tabriz oil refining company owns a 7% share in Iran's refining industry. 90% of this company's products are destined for fuel supply and the remaining 10% are sold on stock market to be used as feedstock in downstream industries.

Q: You recently signed a €1.6 billion deal with South Korea's SKEC to upgrade production. In recent years, optimization projects including its new gasoline production section had become operational. What was the reason for the signature of the deal with SKEC?

A: As I mentioned this company was established 40 years ago. Initially, the refinery was designed in a way to provide 30% fuel oil which was transferred directly to a thermal power plant in Tabriz. However, with the turn of time and improvement in conditions and emergence of environmental obligations and also in consideration of decisions of NIORDC, we and other nine crude oil refining companies in Iran were obligated to reduce our fuel oil production level to below 10%, while at the same time improving the quality of other products to the Euro-5 grade, and reducing sulfur content to below 0.5% weight. Therefore, refinery development projects started in 2007 and the first step was to establish a new gasoline production unit. This unit became operational in 2013 with an investment of €265 million. Currently, 35% of the refinery's gasoline production complies with the Euro-4 standards. In order to bring the grade of remaining production to the Euro-4 standard, the isomerization unit will come online and by the end of the current [calendar] year or at the latest in the first half of the next [calendar] year, quality of the gasoline produced in the Tabriz oil refining company will be in full compliance with the Euro-4 and Euro-5 standards. Furthermore, gasoline refining project or gasoil output quality improvement is set to become operational next February with an investment of €100 million (€70 million for the main project and €30 million for utilities). That would raise the standard of this product to Euro-4 grade.

But improving the quality of fuel oil and converting it to lighter products would need significant investment. It was impossible for us to merely invest in this project; therefore, we sought credit line with a lower borrowing rate. After the implementation of the JCPOA (Iran's nuclear deal with six world powers) by the 11th administration, we embarked on negotiations with several companies, including South Korea's SKEC, which has technology to improve fuel oil production and finance the project. One year ago, feasibility studies for the improvement of fuel oil quality started. Over this period of time, 37 models were presented for the refinery and the most attractive one was chosen.

Q: What was the advantage of the SKEC model compared with others?

A: In addition to the model, the finance of project was of high importance to us. One reason for choosing the company was its specific financing resources. After the JCPOA implementation, we had held talks with companies that could receive credit line. In the end, South Korea managed to provide the credit line via Export- Import Bank (EXIM Bank). Afterwards, a €1.6 billion agreement was signed between Iran and South Korea for optimizing the output of Tabriz oil refining company. The agreement will be in effect for 48 months.

Q: What is the share of South Korea in this finance?

A: At least 75% of financial resources for implementing this project will be provided by South Korea's EXIM Bank. However, we noted in the contract that at least 51% of equipment and technical assistance must be provided by Iran and that equipment which would be manufactured domestically should not be imported. For instance, in the gasoline production unit of the refinery, which came on-stream in 2007, we had to import machinery and reactors. But now all thermal transducers and reactors needed for our projects are made in Iran. Most pumps are supplied by Iranian companies and we have only to import equipment and machinery whose manufacturing is not possible in Iran.

Q: Given the signature of this deal, will we witness more agreements with foreign companies in the future?

A: No, we will no longer sign any agreement with foreign companies for optimizing products supplied by the Tabriz refinery because this section is the last optimization project here; however, I think that we will need to attract foreign investment into petrochemical units over coming five years. Of course, SK has embarked on feasibility studies in this regard, but it does not mean that we will award the project to the Koreans. We intend to have cooperation with other companies, too.

Q: You had earlier said that the Tabriz oil refinery would attract foreign investment. Would you please explain further?

A: The first reason is that we neighbor Azerbaijan, Turkey, Iraq, Armenia and the autonomous Republic of Nakhichevan. In case our need for some products falls in the future, we will have the chance to be present in global markets. Furthermore, after the implementation of this agreement [with SKEC] we will step into regional and global markets for selling our products.

Second, we are the only crude oil refiner with 50% petrochemical share (Tabriz Petchem Plant). We are in fact a petrorefinery and we can convert any surplus products to petrochemicals to be supplied on European markets. In fact, we can develop downstream units and investors could easily be engaged.

Third, we are among the first refining companies in Iran to have received brand permit from NIORDC in the gasoline and gasoil sectors. Multinational companies can produce our high-quality products under our own brand and sell to venues located near the Tabriz oil refining company.

Q: How do you guarantee the sales of your products?

A: Our products enjoy strong technical support. We are the technical base of northwest Iran and we have boosted our experience and technical knowhow in recent years. We own the most hardware-advanced refineries in the refining and oil production phase. It is unique in Iran. We are not worried at all about the market because multinational companies are willing to supply engine oil and gasoline to spots near border via our company. With the signature of this agreement, I think that we can become more active in the regional market in the future and we can export our products to global markets under our own brand.

Q: How many types of products are currently produced at Tabriz oil refinery?

A: This company was producing eight oil products up to 2013; however, we have reached 13 over these four years. We plan to add seven more products to our basket to bring the variety of our products to 20 by the end of the [current calendar] year. That would boost our competitive advantage. We are legally bound to supply our products on domestic markets first. Then our products will be supplied to places which are under our direct supervision. In the final phase we will export surplus products.

Tabriz oil refining company is the only refinery that will produce its own base oil up to the end of the year and then we will try to diversify our base oil production.

Q: How much is the current rate of gasoline and gasoil production at the refinery?

A: We were producing 2.9 mb/d of gasoline by 2013, which has now reached 3.8 mb/d. We are also producing 6 mb/d of gasoil.

Q: What measures have you taken with regard to reducing sulfur production?

A: Establishment of a new gasoil refining unit to reduce the sulfur content of gasoil (from the current 7,000 ppm to below 50 ppm) and increasing the capacity of sulfur production from 60 tonnes a day to 104 tonnes a day are under way. They will become operational this year.

Q: You were recently awarded silver medal for management projects. Would you please tell us about that?

A: Tabriz Oil Refining Company was ranked the second among companies from 54 countries by the International Council of Management Consulting Institutes (ICMCI) and won the 2017 Constantinus International Award. This award goes annually to companies and management consultants which manage to bring about major changes in management, IT and ICT.

Courtesy of Iran Petroleum

Your Comment